Factory Supplier CO2 CNC Laser Engraving Cutting Machine for Acrylic Plywood Leather Paper Logo Engraving with Mixed Metal and Non

Basic Info.

| Model NO. | DXTECH-1325 |

| Cooling System | Water Cooling |

| Technical Class | CO2 |

| Applicable Material | Nonmetal |

| Structure Type | Gantry Type |

| Laser Classification | Hermetic CO2 Glass Tube |

| Control Configuration | DSP |

| Packing | Wooden Box |

| Options | Irregular Rotary/Double Head/ Chiller(Cw3000) |

| Worktable | Honeycomb Worktable/ up&Down Worktable/ Aluminium |

| Cutting Thickness | 0-40mm |

| Cutting Speed | 1-1000mm/Min |

| Certification | CE/ISO/SGS |

| Motor&Drive | Stepper |

| Control System | Ruida Control System |

| Laser Power | 75W-300W |

| Compatible Software | Coreldraw, Autocad |

| Product | CO2 Laser Cutting Machine for Nonmetal |

| Laser Type | Hermetic CO2 Glass Tube |

| Working Table | Blades Working Table |

| Transport Package | Wooden Box |

| Specification | 1300MM*2500MM |

| Trademark | DXTECH |

| Origin | Shandong |

| HS Code | 8461500090 |

| Production Capacity | 300 Per Month |

Packaging & Delivery

Package Size 2500.00cm * 1300.00cm * 1000.00cm Package Gross Weight 1000.000kgProduct Description

Product Description

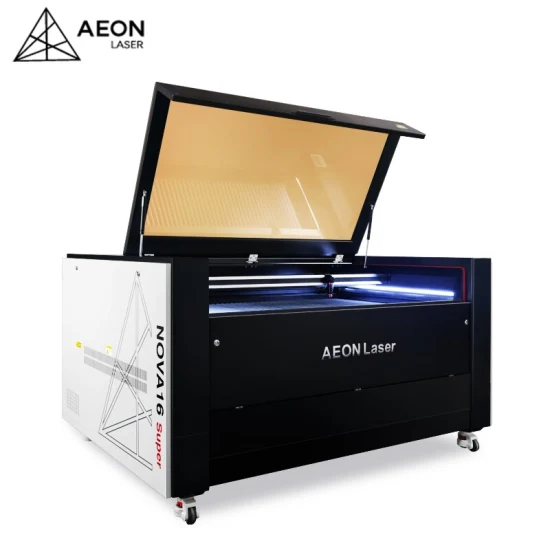

Co2 Laser Cutting Machine for Nonmetal and Metal

This is a powerful co2 laser cutting machine. Adopting non-contact processing, it does not damage the surface of the machined part; does not deform the material. And it can engrave and cut almost any non-metallic material and stainless steel. With advantages of cost-effective, this machine is loved by domestic and foreign users.

Features

* Mixed-cut laser machine: metal steel such as stainless steel,carbon steel,and nonmetal such as acrylic,wood,etc.* High precision: X/Y axis adopt Leadshine servo motor with high precision belt transmission,improve the response speed and cutting precision,extend service life.* Good stability: optimized the nc system control,it can meet the precision parts processing,stable dynamic performance,also can work for long hours.* The cutting section with good quality: mechanical follow-up cutting head system,cutting head always follows the material to keep the cutting point locaation unchanged,which insures smooth cutting section without processing again.It can adopt to flat or curved surface sheet cutting.* Adopt sealed co2 laser tube,main consumable items are electric energy,water cooling,auxiliary gas and laser light.* Simple structure,easy operation,stable laser device and low maintenance cost.

Components

Laser tube

This laser tube has a variety of power 15W-80W for users to choose, and its working service life is can be up to 1800 hours. With long service life, complete functions, fast processing speed, high processing quality, high processing efficiency, stable performance, low maintenance costs, etc. Advantages have been chosen by many users.

Blade table

This kind of industrial laser cutter engraver blade table has a relatively large gap, and the contact surface with the material is relatively small, and the blade can adjust the density, which is very suitable for rigid advertising plates such as acrylic and MDF, reducing the diffuse reflection of the laser on the platform phenomenon to avoid leaving marks on the bottom of the material.

Motor

This motor is known for its stability and speed, high cost performance, and is the world's largest sales brand. It has the characteristics of high speed and stable performance. The rated speed can reach 3000 rpm, which can ensure high speed and high efficiency while ensuring stable operation.

Application

The common processing materials of co2 engraving machine include acrylic, glass, wood, leather, cloth, plastic, two-color board, horn, cardboard, MDF, marble, and other non-metallic materials.

And widely used in advertising processing, gift processing, packaging engraving, leather processing, fabric proofing, seal engraving, product marking, seal engraving and many other industries.

Company Profile